Powder X-Ray Diffraction (P-XRD)

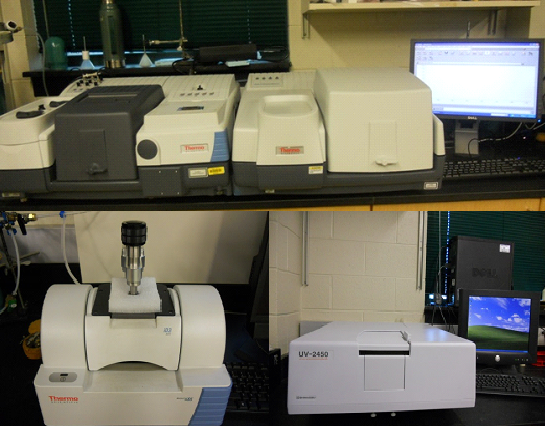

Suib Lab has three Powder X-Ray Diffractometers in-house: A Scintag model XDS 1000, a Thermo-ARL X’TRA, and a Rigaku Ultima IV system, all running Cu K-alpha x-ray emitter tubes. The Thermo-ARL is equipped with an Anton-Parr XRK-900 In-Situ reactor chamber capable of vacuum operation at 10E-5 Torr, Pressurization at 10 Bar, and thermal control to 900°C.

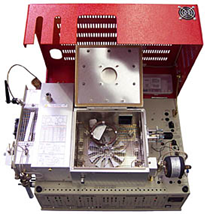

Above from Top Left: Scintag XDS 1000, Rigaku Ultima IV, Thermo ARL X’TRA, ARL X’TRA showing Anton-Parr XRK-900, XRK-900 Sample Mount of Copper Thin Film on Quartz

Cyclic Voltammetry (CV)

Physisorption

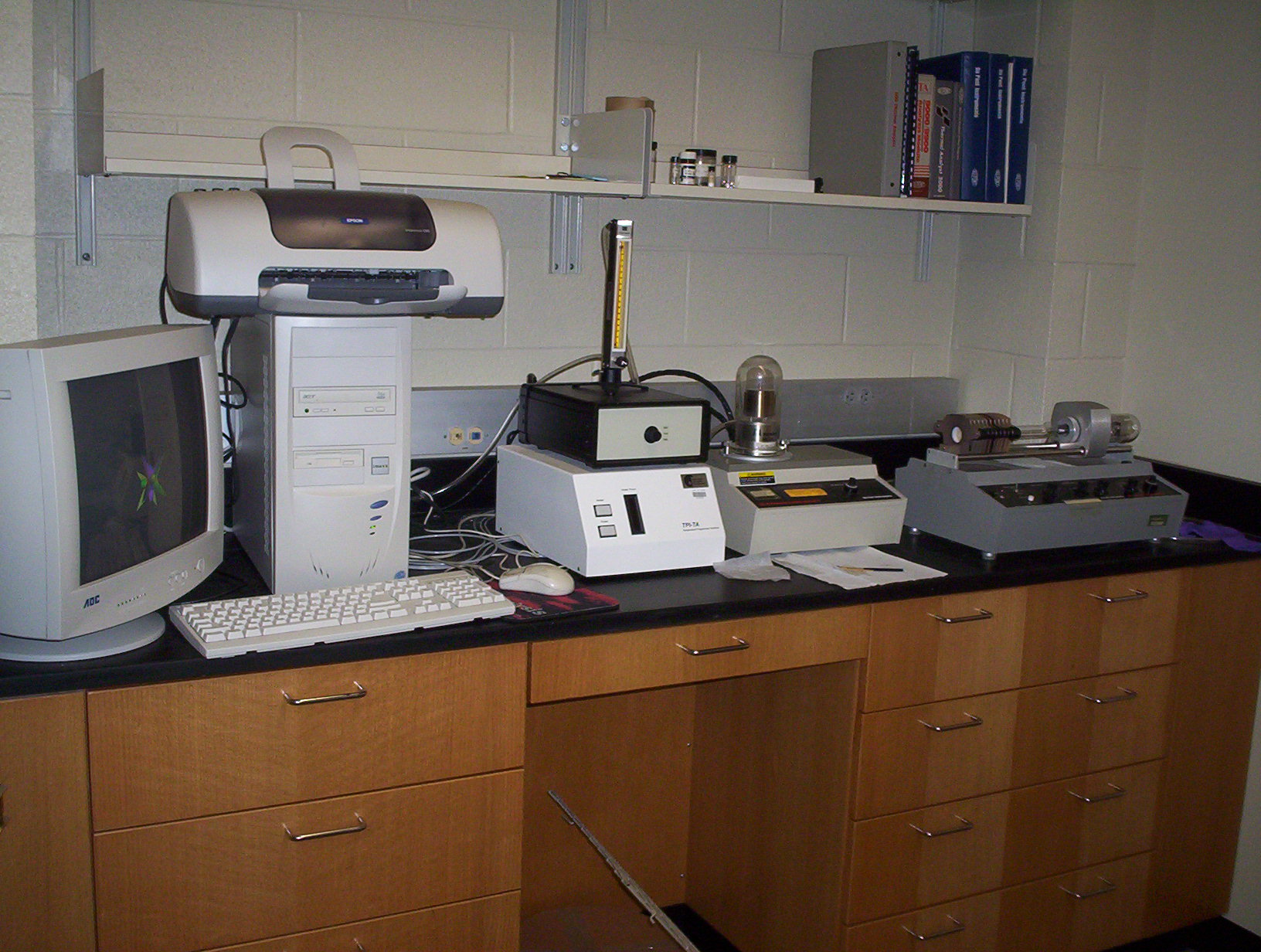

Above Left: Micromeritics ASAP 2010, Above: Quantochrome autosorb iQ2 is a highly sophisticated gas sorption analyzer available with two physisorption analysis ports and provides an easy upgrade path to high vacuum, low pressure and chemisorption capabilities.

Auger

Spectroscopy

UV/VIS

FT/IR, ATR, Raman, Spectroscopy

Residual Gas Analysis- Mass Spectrometry

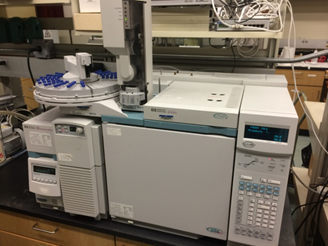

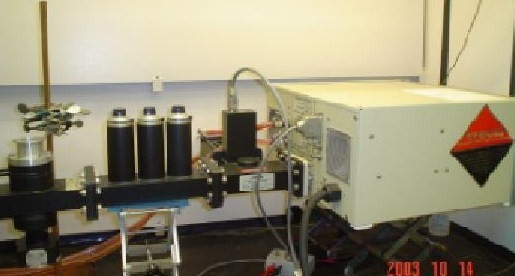

Gas Phase Reaction Evaluation

The laboratory uses a series of gas-phase fixed bed reactors to evaluate materials for catalytic activities, adsorption capacities, material stabilities and a host of other properties.

Liquid Phase Reaction Evaluation

Thin Film Fabrication Facilities

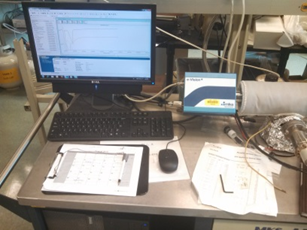

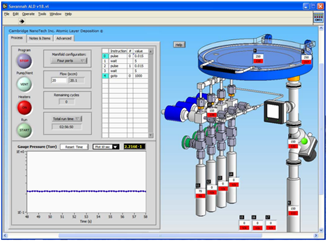

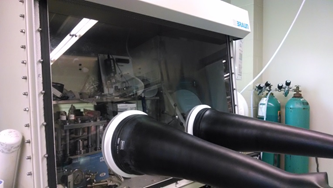

Above from Left, Savannah S100 Control Screen, Denton Benchtop Turbo PVD

Electrochemical and Battery Studies

Above from left: Three-electrode setup for evaluation of Lithium intercalation materials for non-aqueous battery systems. MBraun Glove box containing MTI CR2032 Coin Cell press for fabrication of half-cells and spectroelectrochemical cells.

Ceramics Laboratory

Above: Left: 12” I.D. Low-Pressure Chemical Vapor Deposition Reactor. Right: An inert-atmosphere setup for synthesis of a Pre-ceramic polymer (PCP).

SEM / EDXS

AFM / STM

TGA / DSC

Microwaves

MS