Atmospheric pressure chemical vapor infiltration of a titanium carbide interphase coating on carbon fiber |

|

|

|

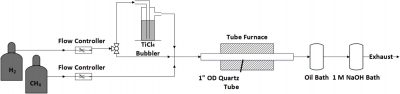

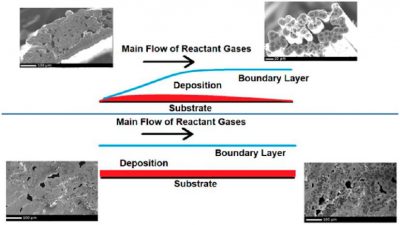

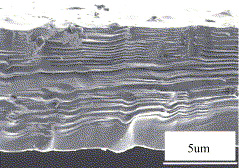

Thin film coatings of titanium carbide (TiC) were deposited onto carbon fibers via atmospheric pressure chemical vapor infiltration (CVI) using TiCl4, CH4, and H2 gases. Three CVI parameters were optimized to obtain high quality coatings: temperature, total gas flow rate, and H2/CH4 flow ratio. Scanning electron microscopy was used to assess the quality and morphology of the coatings, including the roughness, uniformity, fiber coverage, and fiber adhesion. The temperature was optimized to 900 °C, which yielded complete fiber coverage with minimal fiber bridging and good adhesion. Minimizing the total gas flow rate to 37.5 standard cubic centimeters per minute reduced the roughness of the TiC coating. Finally, maximizing the ratio of H2/CH4 to 4:1 was optimal for all coating qualities. Selected area electron diffraction confirmed the presence of crystalline TiC. A combination of transmission electron microscopy and fiber tow tensile testing revealed that the outer layer of carbon fiber becomes damaged by the CVI process, causing loss of strength. To circumvent this surface degradation, it is necessary to protect the fibers with a pyrolytic carbon interphase coating before depositing TiC. This method of depositing TiC onto carbon fibers proves to be competitive in terms of coating quality, deposition temperature, reaction time, and fiber strength compared to other TiC deposition methods including reactive-CVI and molten salt synthesis. |

|

Monteleone, C.; et al. Ceramics International, 2020, 46, 15084-15091 |

|

|

…………………………………………………………………………………………………………………………………………………………………… |

|

Rapid Chemical Vapor Infiltration of Silicon Carbide Minicomposites at Atmospheric Pressure |

|

|

|

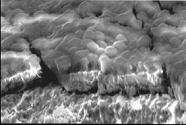

The chemical vapor infiltration technique is one of the most popular for the fabrication of the matrix portion of a ceramic matrix composite. This work focuses on tailoring an atmospheric pressure deposition of silicon carbide onto carbon fiber tows using the methyltrichlorosilane (CH3SiCl3) and H2 deposition system at atmospheric pressure to create minicomposites faster than low pressure systems. Adjustment of the flow rate of H2 bubbled through CH3SiCl3 will improve the uniformity of the deposition as well as infiltrate the substrate more completely as the flow rate is decreased. Low pressure depositions conducted at 50 Torr deposit SiC at a rate of approximately 200 nm*h−1, while the atmospheric pressure system presented has a deposition rate ranging from 750 nm*h−1 to 3.88 μm*h−1. The minicomposites fabricated in this study had approximate total porosities of 3 and 6% for 10 and 25 SCCM infiltrations, respectively. |

|

Petroski, K.; et al. ACS Applied Materials and Interfaces, 2018, 10, 4986-4992 |

|

|

…………………………………………………………………………………………………………………………………………………………………… |

|

|

Characteristics of graphite anode modified by CVD carbon |

|

|

|

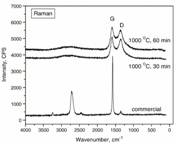

Graphite particles modified with carbon film coating were prepared by a CVD method. Surface characteristics of carbon-coated graphite were analyzed by X-ray diffraction (XRD), Raman spectroscopy, and transmission electron microscopy (TEM). Carbon film was uniformly coated on the graphite surface. Raman, HRTEM, and EELS studies indicated that the structures of the carbon coatings were disordered. Specific surface area of the graphite particles was decreased by carbon coating. Graphite particles coated with carbon were used as anode materials for Li-ion batteries and tested the charge/discharge ability. Uncoated graphite can only achieve 260 mAh/g specific capacity. After disordered carbon was coated onto graphite, the discharge capacity showed an increase up to 300 mAh/g. The anode can achieve a stable discharge capacity and excellent coulombic efficiency after about 60 cycles at 300 mAh/g specific capacity cutoff, and maintain a capacity cutoff of 350 mAh/g capacity without fading after another 30 cycles at a capacity cutoff of 350 mAh/g. The improvements on capacity and cyclability were due to suppression of electrolyte decomposition by the disordered carbon coated on the graphite. |

|

[Surface and Coatings Technology, 2006, 200(9), 3041-3048] |

|

|

…………………………………………………………………………………………………………………………………………………………………… |

|

|

Atmospheric pressure chemical vapor deposition of titanium nitride on metals

|

|

|

|

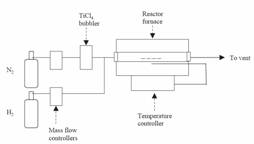

Titanium nitride was deposited onto Ni, Mo and Co metal coupons by atmospheric pressure chemical vapor deposition of TiCl4/N2/H2 in the temperature range of 700 to 800 °C. As the deposition temperature increases, the crystallinity and deposition rates of the TiN coating also increased. Titanium nitride had the highest deposition rate on Ni among the metals. The morphology of the coating was also affected by the deposition temperature being more uniform and smoother at 700 °C and coarse grains started to appear at higher deposition temperatures. The TiN coating roughness is directly proportional to the surface grain size as determined by atomic force microscopy. The surface microstructures of the TiN coating on Mo and Co metal coupons coated at 700 °C consisted of irregular grains and became uneven at higher deposition temperatures. |

|

[Surface and Coatings Technology, 2006, 200(8), 2821-2826] |

|

|

…………………………………………………………………………………………………………………………………………………………………… |

|

|

Direct synthesis of copper faujasite |

|

|

|

Copper containing faujasite has been successfully prepared for the first time using a direct synthesis method. Faujasite type zeolite can be prepared in the presence of copper species by tuning the synthesis conditions. Ammonium hydroxide was used to form a copper complex that was later mixed with the reacting gel. Sodium is required to obtain copper faujasite. The complete elimination of sodium ions from the starting gel produces amorphous material. Crystallization took place at 358 K for 11 days. Crystallization temperature of 373 K produces ANA type zeolite as an impurity. Increasing by two times the amount of copper complex added to the reacting gel increases the crystallization time of Cu-FAU from 11 to 20 days (the crystallization rate decreases). The copper containing faujasite obtained was characterized by XRD, FESEM, EDX, EPR, FT-IR, TPR, and BET. According to the XRD pattern only FAU type zeolite was obtained. According to TPR experiments, the reduction temperature for Cu2+ ions present in Cu-FAU prepared by direct synthesis was 70 K more than for Cu-FAU prepared by ion-exchange. This difference can be due to the different location of the copper ions in the supercages or in the sodalite cages of the faujasite. |

|

[Catalysis Today, 2005, 110(3-4), 323-329.] |

|

|

…………………………………………………………………………………………………………………………………………………………………… |

|

|

Spontaneous and Self-Assembled Line Formations on Silicon Substrates with Vanadium Pentoxide Sol – Gels |

|

|

|

A simple one-pot method has been developed to deposit discreet nanometer line formations on silicon substrates without any surface pretreatment starting with vanadium pentoxide sol-gels. These vanadium suspensions were made by hydrolyzing amorphous V 2 O 5 in water. The properties of the vanadium clusters were determined through X-ray diffraction, elemental analyses, pH calculations, and concentration calculations. Morphology of the lines was examined with optical microscopy, atomic force microcoscopy, and scanning electron microscopy. Infrared spectroscopy was used to inspect the organic components. The vanadium sol-gel used formed discreet and regular lines with high reproducibility and on the same order of magnitude as other patterning techniques. Previous research with a low solubility, 8 g/L, metal oxide for line, ring, or helix formation has not been found in the literature; this work could lead to novel applications of metal oxides such as porous catalysts, battery materials, and resistive electronic materials. |

|

[J. Phys. Chem. B, 2005, 109, 22685-22691] |

|

|

…………………………………………………………………………………………………………………………………………………………………… |

|

|

Preparation Method and Cation Dopant Effects on the Particle Size and Properties of BaCeO3Perovskites |

|

|

|

Perovskite-type BaCeO3 has been investigated to study the effects of preparation method and cation doping on the particle size and sintering in the fabrication of dense perovskite membranes. A variety of preparation methods including solid-state reactions, coprecipitation, microemulsion, and molten salt reactions have been studied. In coprecipitation and microemulsion preparations, perovskites were formed at significantly lower temperatures than that required in a solid-state preparation. The pH of the reactant solutions has been found to greatly affect the particle size and agglomeration of BaCeO3 perovskites. Smallest perovskite particles with sizes of 40�60 nm were obtained by the microemulsion preparation with minimal agglomeration. Transition metal dopants such as neodymium and manganese cations were doped into BaCeO3and their effects on the particle size and agglomeration of perovskite particles investigated. Both small particle size and cation doping significantly helped the sintering of perovskites. |

|

[J. Am. Ceram. Soc., 2005, 88 [10] 2729�2735] |

|

|

…………………………………………………………………………………………………………………………………………………………………… |

|

|

Metal organic chemical vapor deposition of Al2O3 and Cr2O3 on nickel as oxidation barriers |

|

|

|

Aluminum oxide and chromium oxide were deposited onto untreated and pre-oxidized Ni coupons by metal�organic chemical vapor deposition. Oxidizing the surface prior to the deposition of the ceramic coating has been studied to determine the effect of the intermediate oxide layer. The metal oxide coatings were obtained from their respective metal acetylacetonate precursors. The pyrolysis reactions were carried out under atmospheric conditions. Amorphous Al2O3 was obtained at a deposition temperature of 500 °C and crystalline Cr2O3with the corundum structure was obtained at 450 °C. The effectiveness of the metal oxide coatings as barriers were evaluated by oxidation experiments at 800 °C for 120 h. Samples coated with Al2O3 exhibited a significant decrease in oxidation rate. However, Cr2O3 coated on both untreated and pre-oxidized samples were not effective barrier coatings. Samples involving Cr2O3 deposited on untreated Ni showed an increase in oxidation rate whereas samples with Cr2O3 on heat-treated Ni showed a similar oxidation rate as uncoated Ni. The microstructures were investigated with scanning electron microscopy. Composition and crystalline structures were determined with X-ray diffraction and elemental analysis. |

|

[Surface and Coatings Technology, 2004, 186(3), 423-430] |

|

|

……………………………………………………………………………………………………………………………………………………………………

|

|

|

Controlling the growth of CVD carbon from methane on transition metal substrates

|

|

|

|

A hot-wall chemical vapor deposition (CVD) method was employed to grow crystalline graphitic carbon on transition metal substrates. Temperature dependence of the CVD carbon growth and the influence of methane concentration (carbon source) on the growth rate of carbon were systematically investigated. The effect of the substrate on the growth rate and carbon crystallinity was also investigated. These factors, temperature, methane concentration, and type of substrate, influenced the growth of CVD carbon. The carbon growth pattern appears to start with the most crystalline graphitic carbon being produced on the surface of the Fe and Ni and becomes more amorphous as the coating thickness increases.

|

|

[Surface and Coatings Technology, 2005, 190, 366-371] |

|

|

…………………………………………………………………………………………………………………………………………………………………… |

|

|

Synthesis and Characterization of Silicon Nanowires on Mesophase Carbon Microbead Substrates by Chemical Vapor Deposition

|

|

|

|

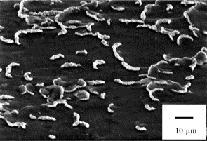

Silicon nanowires (SiNWs) have been fabricated by chemical vapor deposition at ambient pressure using SiCl4 as a silicon source and mesophase carbon microbead powder as a substrate without any templates and/or metal catalysts. The SiNWs have a crystalline core with a very thin amorphous SiOx sheath. The obtained SiNWs are homogeneous with average diameters below 50 nm and lengths up to micrometers. Temperature and time effects on the growth of SiNWs were systematically studied. Higher reaction temperatures and longer reaction times resulted in larger diameters and higher yields of SiNWs. SiNWs with a better crystallinity can be obtained at higher temperatures and longer reaction times. The obtained SiNWs were characterized by field-emission scanning electron microscopy, X-ray diffraction, Raman spectroscopy, and transmission electron microscopy.

|

|

[J. Phys. Chem. B, 2005, 109, 3291 – 3297] |

|

|

…………………………………………………………………………………………………………………………………………………………………… |

|

|

Metal organic chemical vapor deposition of Al2O3 and Cr2O3 on nickel as oxidation barriers

|

|

|

|

Aluminum oxide and chromium oxide were deposited onto untreated and pre-oxidized Ni coupons by metal-organic chemical vapor deposition. Oxidizing the surface prior to the deposition of the ceramic coating has been studied to determine the effect of the intermediate oxide layer. The metal oxide coatings were produced by metal organic chemical vapor deposition. The pyrolysis reactions were carried out under atmospheric conditions. Amorphous Al2O3 was obtained at a deposition temperature of 500 °C and crystalline Cr2O3 with the corundum structure was obtained at 450 °C. The effectiveness of the metal oxides coatings as diffusion barriers were evaluated by oxidation experiments at 800 °C for 120 h. Samples coated with Al2O3 exhibited a significant decrease in oxidation rate. However, Cr2O3 coated on both untreated and pre-oxidized samples were not effective diffusion barriers. Samples involving chromium oxide deposited on pristine Ni showed an increase in oxidation rate whereas samples involving Cr2O3 on heat-treated Ni showed a similar oxidation rate as uncoated Ni. The microstructures were investigated with scanning electron microscopy. Composition and crystalline structures were determined with X-ray diffraction and elemental analysis.

|

|

[Surface and Coatings Technology, 2004, 186, 423-430] |

|

|

…………………………………………………………………………………………………………………………………………………………………… |

|

|

Aluminum Oxide and Chromium Oxide Coatings on Ceramic Fibers via MOCVD

|

|

|

|

The overall strength and toughness of ceramic matrix composites is very much affected by the interfacial properties that govern the bonding between the reinforcing fibers and the matrix. The ability to control this interaction is very important. One method involves coating the ceramic fibers with an appropriate material. There is a definite advantage in using lower temperature processes to produce the coatings; fibers subjected to high temperature coating processes are more prone to degradation due to microstructure and crystallization changes. Matrix and fiber materials could also react at high temperatures forming a strong bond at the interface making the composite brittle. Metal-organic precursors were used to produce aluminum oxide and chromium oxide coatings on SiC and Al2O3-SiO2 based ceramic fibers. These metal oxides were deposited on the reinforcing fibers by the pyrolysis in air of their respective metal acetylacetonates at temperatures of 500 °C or less. The coated ceramic fibers showed some reduction in tensile strength but still had considerable strength for use in composites. |

|

[Chemistry of Materials, 2003, 15, 4823-4829] |

|

|

…………………………………………………………………………………………………………………………………………………………………… |

|

|

Aluminum oxide coating on nickel substrate by metal organic chemical vapor deposition

|

|

|

|

Alumina thin films were coated onto nickel substrates via MOCVD. The alumina was produced by pyrolysis of aluminum acetylacetonate precursor. This reaction was done at relatively low temps., from 435-550 °C to deposit a thin film of alumina. The coating provided protection against isothermal oxidn. at elevated temps. Resistance to oxidn. was obtained for all of the coated substrates. Surface morphol., however, changed when heated for prolonged time. Samples coated at 500 and 550 °C were effective < 900 °C whereas samples coated at 435 °C were good < 800 °C. The metal oxide compns. and phases were studied by x-ray diffraction and EDAX. The surface properties of the deposited thin films were investigated with SEM. |

|

[Surface and Coatings Technology, 2003, 173, 74-80] |

|